Ultimate process reliability at uniformly and clean application of lubricants even with the smallest dosing volumes. With the ABNOX metering valves, you apply the exact dosing quantities of your complex lubricant even more precisely to your components. Precise and clean application at high repeatability means permanent saving of your expensive lubricant!

Sensors to monitor the position of the grease piston may be retrofitted at any time. They increase the effectivity and reliability of the greasing operation, and allow improved control over your production and assembly process!

The electronic position switch is available as accessory, Art.No. 0001220. It may be attached to the grooves of the metering valve by means of an attachment screw in a continuously variable position. Furthermore, the operation display (LED) indicates the end position of the grease piston. To achieve highest process reliability, ABNOX recommends the use of position switches on both end positions.

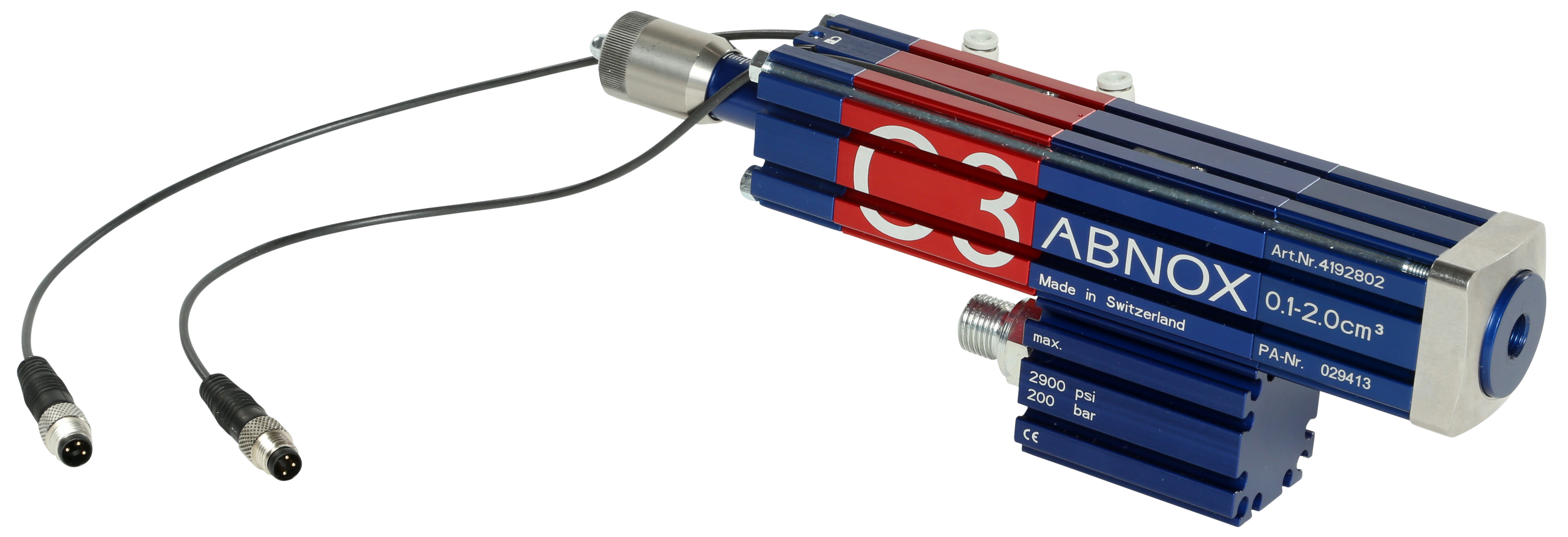

The volumetric metering valve has a continuously screw-adjustable dosage chamber, as well as an integrated pneumatic cylinder to control the dosage pin.

A hexagon key wrench with hex. 1.27 mm for the series C1/C2 and with hex. 2.00 mm for the series C3/C4 (included in scope of supply) is used to lock the adjustment screw. Accidental misadjustment of the dosage volume is therefore a matter of the past.

For external control for the metering valves with assembly block, a simple pneumatic 5/2-way valve is required. To control the dosing process with the shortest switching distances directly on the metering valve, we recommend control with our upgrading option electro-pneumatic solenoid valve.

On the metering valves with handgrip (models PN/HG/SV), the pneumatic part of the metering valve is controlled by a 5/2 way valve which is located inside the handle. Pressing the trigger initiates ejection of the metered medium. The output pressure depends on the lubricant feed pressure (media). The pneumatic system is separated from the grease chamber. The metering tolerance is maintained to better than +/- 2% in the middle range of dosage volume

ABNOX metering valves of the series with handgrip (models PN/HG/SV) are suitable for all and especially for vertically accessible lubrication points. The ergonomic and shapely handle with modern and optimised metering activator is especially suited for easy and handy operation of the metering valve at installation sites. Handling of these metering valves may be further facilitated by using a counterbalance suspended directly above the assembly area.

All ABNOX metering valves are equipped with modern seals and glydrings, they warrant a long lifespan even at operating pressures as high as 200 bar.

Besides metering valves for various dosage volumes, ABNOX provide suitable conveyor pumps and ancillary equipment for complete solutions to your lubrication process. With the standard nozzles ABNOX Ltd. constructs specific customised application nozzles which can be directly screwed to metering valve.

Dosing monitoring made easy

In order to maximise the process reliability of volumetric dosing valves, ABNOX recommends the monitoring device with LED display, see accessories, art. no.: 001254X and the film below: LED box.

With this small but fine option, semi-automatic greasing at manual workplaces is set to a top level.

| 4191802 | Standard (Assembly Block) |

|---|---|

| 4191803 | Standard (Assembly Block) |

| 0004998 | Standard (Assembly Block) |

| 0008528 | Standard (Assembly Block) |

| 4192302 | Standard (Assembly Block) |

| 4192303 | Standard (Assembly Block) |

| 0004997 | Standard (Assembly Block) |

| 0011524 | Standard (Assembly Block) |

| 4192802 | Standard (Assembly Block) |

| 4192902 | Standard (Assembly Block) |

MasterCal, a specialized vertical of Master Linque Automation, delivers world-class industrial solutions to Indian manufacturers in partnership with Abnox (Switzerland) and CEIA (Italy)—ensuring reliable, production-grade results backed by a decade of automation expertise.